Any questions ? Our technical and commercial teams will be glad to help - contact-us

Our XALIS installed at the Qianwei hydroelectric power station in Minjiang

The Qianwei hydropower plant is located in Qianwei county, Leshan city, Sichuan province, China. It is located on the Minjiang River, a major tributary of the Yangtze.

Commissioned in 2020, the power station has an installed capacity of 500 megawatts (MW), divided between nine 55.6 MW turbines. It operates on the “run-of-river” principle, exploiting the river's natural flow without the need for a large reservoir.

The project is owned and operated by Sichuan Port and Shipping Investment Group (SPSI).

The Qianwei power plant makes a significant contribution to renewable energy production in the Sichuan region, supporting China's efforts to diversify its energy mix and reduce greenhouse gas emissions.

This navigation and hydropower project is composed of 4 parts:

- A hydroelectric power plant with a total capacity of 500 MW, comprising 9 horizontal bulb generators (Kaplan turbine + alternator). They are equipped with a turbine that transforms the energy of the water flow into mechanical rotation to drive the alternator. The turbines are horizontal-flow Kaplan turbines. A transformer downstream of the alternator increases the voltage of the electricity produced from 10.5KV to 220KV.

- A reservoir management process with several discharge valves. This regulates the flow of water, stores water for the hydroelectric plant and reduces the risk of flooding.

- A lock to enable boats to navigate upstream and downstream of the dam, while avoiding sudden changes in water level.

- A fish passage to facilitate fish passage from one side of the dam to the other.

Monitoring friction-generated temperature in hydroelectric turbines

In a hydroelectric power plant such as Qianwei, turbines convert water energy into mechanical energy, then into electricity via alternators. These turbines operate at high speed and are subject to considerable mechanical forces.

One of the major problems encountered in such equipment is the heat generated by friction, which can come from several sources, including:

- Bearings: Critical components that support the axes of rotation and which, under heavy load, can generate heat through friction.

- Seals: These are subject to high pressure and constant friction.

- Mechanical clearances: misalignment or premature wear can lead to abnormal heating.

- Fluid-material friction: Contact between water and certain metal parts creates hydrodynamic friction.

Why is temperature monitoring essential?

Excessive temperature rise can lead to :

- Accelerated wear of components (bearings, seals, etc.).

- Mechanical expansion, which can lead to malfunctions (misalignment, excessive vibration).

- Fire hazard in lubricated areas.

- Loss of energy efficiency, as overheated turbines may experience reduced performance.

- Unplanned shutdowns, leading to high maintenance and downtime costs.

The role of electrical signal conditioning devices

Electrical signal conditioning devices play a key role in monitoring. They enable :

- Capture data in real time: Temperature sensors are installed on critical parts (bearings, seals) and transmit electrical signals to conditioning devices.

- Filter and process signals: Devices ensure accurate conversion of measurements to avoid interference or reading errors.

- Issue alerts: If predefined temperature thresholds are exceeded, an alert is sent to warn maintenance teams.

- Analyze trends: by recording data, it is possible to anticipate breakdowns by detecting unusual overheating patterns.

- Ensure integration with the control system: They transmit data to PLCs, which can automatically adjust certain parameters (water flow, lubrication, emergency stop).

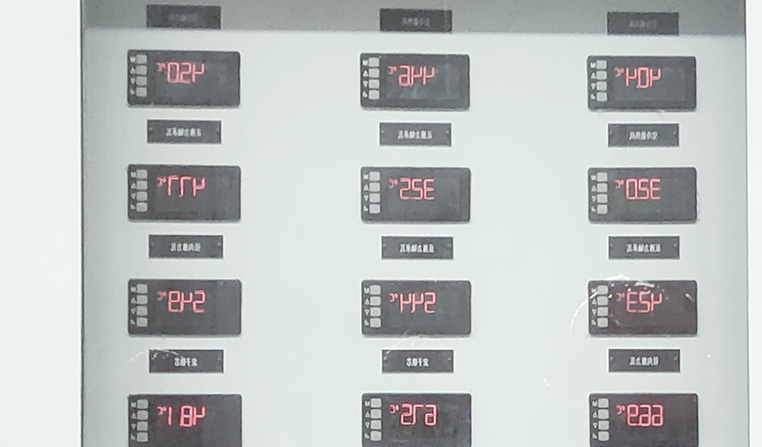

The Qianwei hydropower plant has chosen to use our XALIS 3400P1 two-color digital indicators. They are used in the following configuration:

- Input = 3-wire RTD

- Output = Current 4-20mA.

Our XALIS are used to continuously monitor the temperature generated by friction (to prevent overheating and axis misalignment). This ensures optimum, safe turbine operation. Each generator uses 16 XALIS, giving a total of 144 XALIS 3400P1 devices (16 XALIS * 9 Generators = 144 XALIS).

Our XALIS digital indicators play an essential role in alarm and safety management. The first two relays are dedicated to overshoot alarms, while the 3rd relay ensures system shutdown. The 4th relay is used in the event of signal loss or sensor breakage.

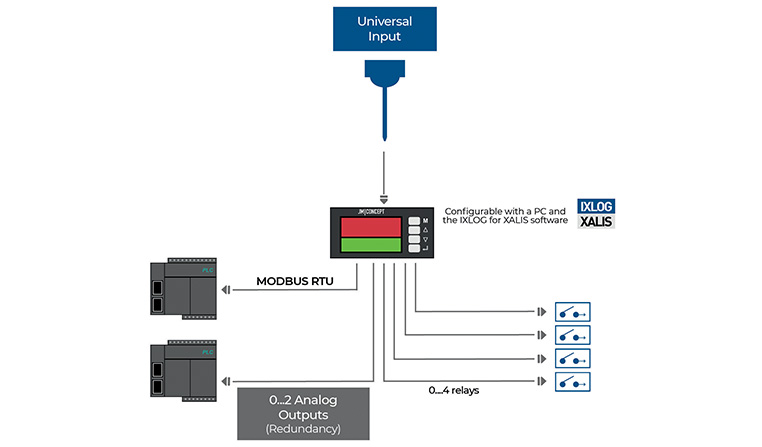

Our XALIS 3000 indicator is a range of digital indicators with a two-color display for analog and digital transmission of various signals.

Our XALIS 3400P1 indicators feature a universal input, an analog output and 4 relay outputs.

The universal input of our XALIS 3400P1 indicators offers maintenance personnel flexibility and compatibility. In fact, this device can receive signals from various types of sensor, such as temperature, pressure, etc. This offers several advantages:

- Adaptability to several types of sensor without the need for additional modules.

- Reduced integration costs by using a single device for different measurements.

- Simplified maintenance and operation thanks to a unified interface.

The analog output of our XALIS 3400P1 indicators facilitates supervision and automation. Often in 4-20 mA or 0-10 V, it enables measured values (temperature, pressure, vibration) to be sent to third-party systems such as PLCs, SCADA systems, converters or variable speed drives.

- Integration with existing control systems is easy.

- Automated reactions are made possible (e.g. increased lubrication flow in the event of overheating).

- Continuous monitoring prevents unplanned downtime.

The relay outputs of our XALIS 3400P1 indicators can trigger immediate actions according to programmed thresholds, such as :

- Trigger visual/audible alarms when critical temperatures are exceeded.

- Emergency turbine shutdown to prevent catastrophic damage.

- Activation of cooling or lubrication systems to regulate temperature.

- Signal to an operator or send alerts to a control room.

- Trigger relays manually using front-panel buttons. A feature appreciated by our customers in the event of PLC failure.

- Error response time can be programmed directly on the device. In this way, certain interfering signals can be ignored.

The ability to trigger these immediate actions enables you to

- Proactively protect equipment in the event of abnormal conditions.

- Reduce response time when thresholds are exceeded.

- Increase operational safety through automated, programmed actions.

We thank ou client for its trust !