XALIS 1000U1SIL - Strain Gauge Input Indicator with 1 Analog Output - SIL 2 Certified

Discover

Any questions ? Our technical and commercial teams will be glad to help - contact-us

The lifting industry includes all activities related to the design, production, sale and use of lifting equipment such as

Lifting companies often provide rental, maintenance and training services for users of their products.

This industry is crucial to many other industries, such as construction, metallurgy, logistics and load handling. Lifting equipment is used to lift and move heavy and bulky loads, facilitating the construction of buildings, the production of manufactured goods, the storage of products and the delivery of goods.

The lifting industry is constantly evolving, with new technological developments such as robotisation and digitalisation leading to greater efficiency, safety and productivity. Lifting companies are required to comply with strict safety standards to ensure the safety of workers and consumers.

The lifting industry plays a crucial role in many industries, enabling heavy loads to be moved safely and efficiently. However, with increasing safety and performance requirements, companies in the sector must constantly innovate to improve their equipment and processes.

As a manufacturer of signal processing modules, specialising in the isolation, measurement, conversion and transmission of all types of sensor signals or electrical quantities, we are well aware of the challenges faced by those involved in industrial lifting. In this white paper, we highlight our solution for the industrial lifting sector: a SIL2-certified product, capable of connecting and displaying signals from strain gauges while creating secure analogue signals, or actuating relays.

Industrial lifting is an essential activity in many sectors, such as construction, logistics and manufacturing. However, due to the nature of the loads handled and the complex working environments, safety is of paramount importance in this field. Lifting accidents can result in serious injury, property damage and even loss of life. As a result, industrial lifting companies are obliged to put in place rigorous safety measures to protect their employees, their equipment and their environment.

To ensure high safety standards in the industrial lifting sector, numerous regulations and standards have been established. These rules aim to establish clear guidelines for the design, manufacture, operation and maintenance of lifting equipment. Among the most commonly observed regulations are European directives such as the Machinery Directive (2006/42/EC) and the Pressure Equipment Directive (2014/68/EU). In addition, international standards such as ISO 13849 and IEC 61508 play a key role in assessing the safety of control systems.

SIL (Safety Integrity Level) certification is a standard that evaluates and attests to a system's level of safety integrity. It is often required in industrial environments where safety is paramount, such as industrial lifting. SIL certification guarantees that equipment and systems meet specific requirements in terms of reliability, fault tolerance and ability to prevent critical failures. These certifications provide companies and end-users with additional assurance about the safety and performance of lifting equipment.

Signal processing plays an essential role in industrial lifting equipment. Sensors and strain gauges are used to measure and monitor parameters such as load, tension, pressure and position, providing crucial information to ensure the correct operation and safety of lifting equipment. However, processing these signals presents particular challenges:

By understanding the challenges associated with signal processing in lifting equipment, manufacturers can develop innovative solutions that improve safety, performance and compliance with industry standards.

In summary, safety is of paramount importance in the industrial lifting sector, and current regulations and standards, as well as SIL certification, play a vital role in ensuring safe and reliable lifting equipment. The challenges associated with signal processing require specialised, SIL2-certified solutions to ensure accurate measurement, secure transmission and signal integrity in industrial lifting equipment.

The new product developed is an indicator XALIS 1000 SIL2. The XALIS 1000 is a digital indicator with one input dedicated to strain gauge measurements (in 4 and 6 wires) and one input for the taring function. It drives 1 or 2 analogue outputs and up to 4 relay outputs.

The indicator XALIS 1000 complies with the SIL2 standard (IEC 61508), both in 4-wire and 6-wire versions, improving product reliability and safety. The indicator XALIS 1000 SIL2 can therefore be used in a SIL2 or PL-d measurement and control chain to ensure the safety of people and property.

The indicator XALIS 1000 SIL2 has all the functions of the XALIS 1000, but is restricted for use in safety applications.

There are 3 operating phases:

The new product on the market is a SIL2 product which measures a 4 or 6 wire strain gauge, has the following features:

As the new product is based on a XALIS 1000 indicator, the new functionality to be developed is to ensure that the product complies with the SIL2 standard, with a product reliability rate of over 90%.

The safety level of the product's main function, which is to measure an input weight and act on the analogue and relay outputs accordingly, has been strengthened.

In order to achieve the desired level of reliability, software and hardware developments have been taken into account:

Industrial lifting equipment often requires relay or analogue signals to perform control and command actions. Relay signals are used to activate or deactivate important electrical circuits, such as motors and brakes, while analogue signals are used to provide continuous information, such as speed, position or load. These signals are essential to ensure precise, safe and synchronised operation of the various components of lifting equipment.

Strain gauges play an essential role in industrial lifting by enabling the precise measurement of loads and stresses applied to lifting equipment.These sensitive devices transform the mechanical deformation resulting from loads into proportional electrical signals. Strain gauges are usually fitted to the structural components of lifting equipment, such as beams, cables or cylinders, and monitor variations in stress in real time. This information is vital for assessing the safety and load capacity of equipment, detecting potential overloads and preventing structural failure. Using strain gauges, operators can adjust operating parameters, optimise lifting efficiency and ensure a safe and reliable working environment.

Our SIL2-certified signal processing modules are designed to meet the stringent requirements for the conversion and transmission of relay or analogue signals. They incorporate high-precision conversion circuitry that transforms incoming signals into a form compatible with lifting equipment control systems. In addition, our modules offer robust galvanic isolation to protect against electromagnetic interference and short circuits, ensuring safe signal transmission over long distances.

The SIL2 requirement assumes that the product is used under the conditions specified in the declaration of conformity. The conditions of use are as follows:

In operation, the XALIS 1000 SIL2 indicator:

The use of SIL2-certified relay and analogue signals in lifting equipment has many practical applications. For example, in lifting cranes, our modules can be used to create SIL2-certified relay signals to control arm movement, boom rotation or the locking of lifting mechanisms. Similarly, in industrial lifts, our modules provide accurate conversion of analogue signals from position or load sensors, facilitating closed-loop control of speed, position and timing of movements. These features ensure optimum accuracy and reliability, improving the safety and overall performance of industrial lifting equipment.

SIL2 (Safety Integrity Level) certification is an international standard widely recognised in high-risk industries, including industrial lifting. It assesses the level of safety integrity of a system or component and ensures that it is designed, manufactured and tested to strict standards. SIL2 certification requires an exhaustive risk assessment, redundant design, failure prevention measures and detailed documentation. It certifies that the system is capable of preventing or limiting the consequences of dangerous events and maintaining a high level of safety.

To validate the XALIS1000 SIL indicator, JM Concept carried out a series of tests to validate the product. All the test reports were sent to an independent certifier so that it could review the various validation activities.

This certifier reviewed the various test reports in order to assess the completion of the integration and validation tests. The validation tests carried out fall into two categories: environmental tests and functional tests.

The environmental tests include EMC tests on the XALIS1000 SIL and temperature resistance tests at the board's maximum and minimum temperatures. In these environmental tests, the XALIS1000 SIL is also tested in a column layout of the product. To carry out the functional tests, JM Concept divided the XALIS1000 SIL into different sub-functions in order to carry out tests for each of its sub-functional blocks. Among the functional validation tests, the following stand out as being important

JM Concept used the XALIS1000 SIL indicator design plan as a starting point and then took a systematic approach to validating all the parts (sub-functions) of the component.

The certifier believes that this approach covers the majority of the XALIS1000 SIL's functionalities and enables the most critical functions to be tested. In this way, the validation of the XALIS 1000 SIL meets the major requirements of IEC 61508 ed.2.0.

The use of SIL2-certified modules offers a number of advantages for industrial lifting equipment. Firstly, these modules improve safety by minimising the risk of accidents or critical failures. They ensure high signal integrity, reducing measurement errors and false commands. In addition, SIL2-certified modules offer increased reliability thanks to their redundant design and their ability to detect potential faults. This improves the availability of lifting equipment and reduces unplanned downtime. Finally, the use of SIL2-certified modules facilitates compliance with current standards and regulations, increasing the confidence of end-users and regulators in the safety and performance of industrial lifting equipment.

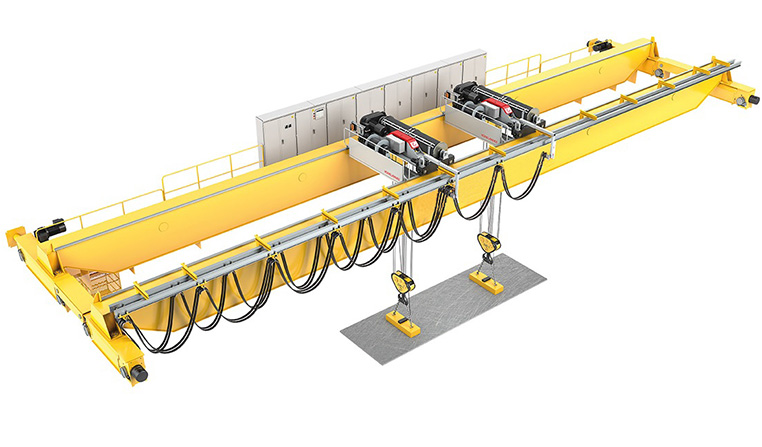

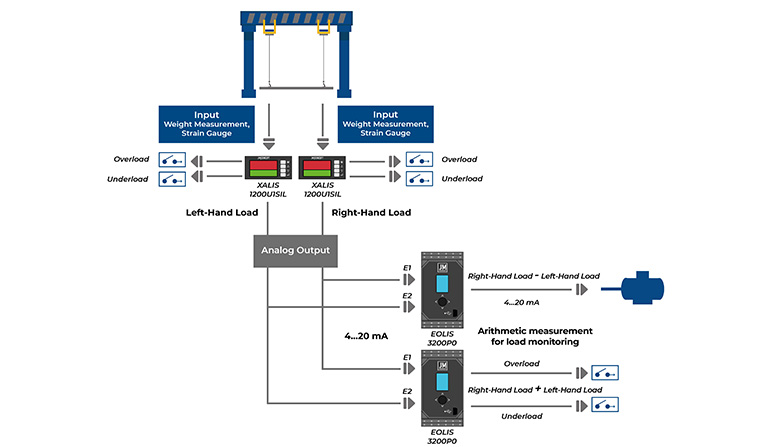

Our customer installed XALIS 1200U1 devices to display the load measured by dynamometric pins on a lifting bridge. They indicate the load (with an "overload" and "underload" safety system) and then send the information in 4...20mA to EOLIS 3200P0 transmitters. These transmitters check the balance of the part and transmit the information to the device that controls the speed of motors 1 and 2.

Our devices control the total weight lifted by the crane, and prevent overloading or underloading, thanks in particular to the threshold relays, enabling the process load balance to be monitored.

Our XALIS 1200U1 indicators are available in SIL version and are the ideal choice for this weight control application, as they guarantee increased safety in lifting operations. In fact, our XALIS 1200U1SIL indicators are capable of generating a voltage or current output signal representative of a strain-gauge input variable. They can also switch relay outputs to a fallback position when an operator-defined threshold is exceeded. And if a fault is detected, fallback modes or safe states are defined on the analogue and relay outputs.

Our customer has been eagerly awaiting them, and we're delighted to be able to meet their needs with an optimised and even more secure solution.

In this white paper, we highlight the importance of signal processing in the industrial lifting sector and present our SIL2-certified solution for this field. By using our signal processing modules, lifting companies can improve the safety, performance and reliability of their equipment while complying with the most stringent standards.

Our customers' commitment to maintaining and regularly updating their lifting equipment is essential to ensure optimum performance. As outlined in our SIL2 certified signal processing solutions documentation, meeting current standards is not just a matter of compliance, but also a key factor in the reliability and efficiency of their operations.

Contact us today to find out how our solution can meet your specific industrial lifting requirements.