JK 2001 - Single-Channel Self-Powered Loop Isolator

Discover

Any questions ? Our technical and commercial teams will be glad to help - contact-us

Is galvanic insulation crucial to your process? CONTACT US

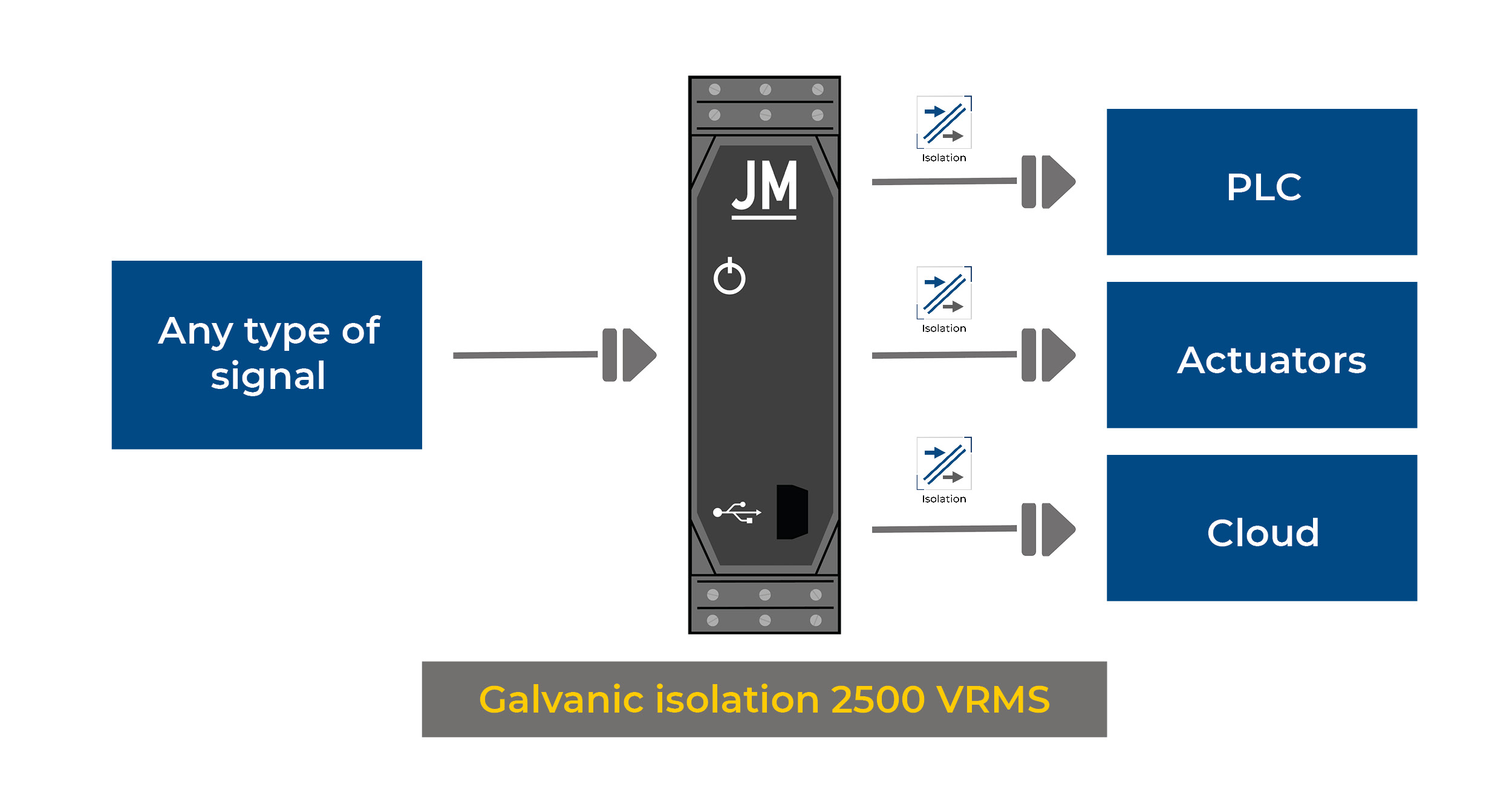

Galvanic isolation is the technique of electrically separating two parts of a system to prevent the flow of direct electrical current between them. The main aim of galvanic isolation is to guarantee total electrical separation between circuits or equipment, even if they share a physical connection.

Did you know?

Galvanic isolation plays a major role in the world of industry, as it enables you to:

1/ protect your equipment

2/ improve safety

3/ guarantee optimum operation of instrumentation and process control systems

Indeed, one of the most common causes of measurement errors, noise sources and damage to connected PLCs is incorrect earthing of the system.

At JM Concept, we have the solution! We design, manufacture and market devices for conditioning electrical signals for measurement:

While our devices have 4 major features that make them unique, today we'd like to talk to you about the galvanic isolation of all our solutions, whether for:

1/ Galvanic isolation of our devices eliminates common-mode voltage errors and ground loops, generally caused by differences in earth potential.

2/ Galvanic isolation protects sensitive equipment by preventing the propagation of overvoltages from one circuit to another. It therefore helps protect electronic components in the event of sudden voltage variations.

3/ The galvanic isolation of our products is the best in its class on the market (2500VRMS Inputs - Outputs - Power supply). In this way, both maintenance operators and equipment are protected from major disturbances.

4/ By preventing the direct flow of current between two parts of a system, galvanic isolation helps to improve safety by reducing the risk of electrocution and fire.

5/ In industrial installations, different equipment may have different electrical potentials. Galvanic isolation makes it possible to connect such equipment without creating a ground loop, thus avoiding undesirable potential problems.

6/ By preventing the propagation of faults from one component to another, helps to improve system reliability. Localized failures are less likely to spread to other parts of the system.

Introduced to the market in 1992, our very first product was the JK 2000 self-powered galvanic isolator. This device has been around since the company's earliest days, and remains a flagship product in the range today. It is distinguished by its extremely low internal voltage drop. Since the JK 2000 isolator, we have been scrupulously dimensioning the galvanic isolation of the entire range, and it has become a key element in our DNA. This unrivalled galvanic insulation is recognized and sought-after by our customers, who see it as a guarantee of the reliability of our products, a reliability that was also mentioned many times in the satisfaction survey we carried out last year. ⬇️

JK 2001 - Single-Channel Self-Powered Loop Isolator

Discover

JK 2001D - Single Channel Self-Powered Loop Isolator - Swappable Plug In and Out

Discover

JK 2002 - Dual-Channel Self-Powered Loop Isolator

Discover

JK 20S1 - Single-Channel Self-Powered Loop Isolator with Modified Output Impedance

Discover